Cooling Tower Tank Lining & Epoxy Paint Coatings

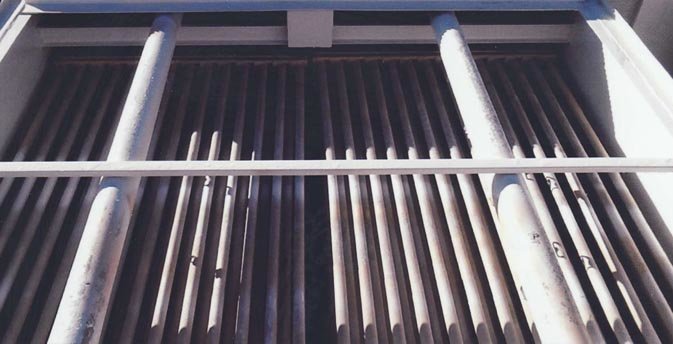

Cooling towers are very important for making sure that big HVAC and industrial systems work well. But their tanks might wear out over time because they are always exposed to water, chemicals, and changes in temperature. If these problems aren’t fixed right away, they can lead to costly repairs or even a complete system failure.

That’s when cooling tower tank lining and epoxy paint coatings can help. These particular coatings provide a barrier that protects your cooling tower tank from chemicals, rust, and other things that could shorten its life. If your system is in Arizona, you already know how hot it can get and how mineral-rich water can speed up wear and tear. This makes expert lining services more critical than ever. Read on to learn more.

Why Tank Lining Is Important

Cooling towers always move water around, and that water often has minerals, chemicals, and living things in it. Over time, these things wear down the steel or concrete walls of the tank. A good epoxy tank lining keeps the metal or concrete from coming into contact with the water that is circulating. If you use the appropriate lining correctly, it can make your equipment last 10 to 20 years longer.

Advantages of Using Epoxy Coatings on Cooling Towers

Epoxy coatings are the best way to keep tanks from rusting and being damaged by chemicals. They stick closely to steel and concrete surfaces, making a smooth covering that keeps moisture from getting in.

Some of The Main Benefits Are:

- Corrosion Resistance: Keeps metal tanks from rusting and oxidizing.

- Chemical Protection: It can handle severe cleaning solvents, scale inhibitors, and other chemicals used in treatments.

- Easy to Clean: Smooth, non-porous surfaces make it hard for bacteria and scale to grow.

- Durability: Epoxy coatings can handle changes in pressure and extreme temperatures.

- Cost-Effectiveness: It’s a lot cheaper to extend the life of your tank than to buy a new one.

The Process of Lining and Coating

It’s very important to have a professional do the work on your cooling tower tank lining to make sure it works as it should. For example:

- Removing rust, old coatings, and dirt from the surface by sandblasting or pressure washing.

- Fixing and Patching: Cracks, pits, or other damaged areas are fixed to make the base smooth.

- Using Primer: A bonding primer helps the epoxy stick to the surface.

- Epoxy Coating: The lining is put on in several layers to make a robust, protective shell.

- Curing and Checking: The coating is left to cure completely before being checked for even coverage and adhesion.

Things To Think About in Arizona

Water conditions can be really bad here in Arizona. All Kote Lining Inc. employs industrial-grade epoxy coatings that are made to work in settings with a lot of heat and minerals. These coatings stay strong even when the temperature changes a lot, which is great for cooling towers that have to deal with Phoenix’s harsh weather.

You Can Trust The People At All Kote Lining Inc.

All Kote Lining Inc. can make custom solutions for any kind of cooling tower or water system. Their crew makes sure your system stays efficient, reliable, and safe all year round by doing anything from inspections and cleanings to full relining and recoating.

Phoenix Cooling Tower Cleaning

If you have a commercial property it is important to keep the cooling tower disinfected and clean. The spread of bacteria from the cooling tower poses and health concern for your visitors and costs you money in energy costs. Before you fire up a cooling tower that has been shut down for the season, or for a longer period of time, it must be inspected, cleaned, and disinfected. This helps fight the spread of disease and cuts down on your overhead. To get your cooling tower cleaned call All Kote Lining at 480-966-4446.